- Polyester (PE)

The basis of this coating is polyester. The material has long been used in the manufacture of metal tiles, has a glossy appearance and is distinguished by its ductility and high color stability.

Metal coating made of polyester, shiny, smooth, relatively inexpensive. It is highly resistant to corrosion and ultraviolet rays, that is, it will not fade under the sun for a long time. However, in thin layers (up to 30 μm), it is damaged by light mechanical stresses, for example, when snow layers gather from the roof. Do not use polyester where weather conditions are unfavorable.

- Matte Polyester (PEMA)

Among types of metal tile coatings matte polyester looks most attractive. This is polyester in which Teflon is added to create a matte finish. In addition to resistance to UV rays, it also has increased resistance to mechanical damage due to the increased coating thickness (35 μm). Even in difficult weather conditions, it will last a long time.

- Pural (PU)

Pural Coated Metal based on polyurethane, the molecules of which are modified by polyamide. The coating thickness is 50 μm, which gives it additional mechanical stability. Ultraviolet light and even chemically aggressive substances, such as acids that precipitate in areas with polluted air, do not change the properties. pural coated metal tiles. It serves for a long time without changing color and mechanical resistance in any conditions.

The surface of such a metal tile is silky to the touch and matte in appearance. Due to the properties of the pural roof with such a coating is easy to handle and install. The temperatures at which it retains its properties are from minus 150 to plus 1200 degrees Celsius.

- Plastisol (PVC)

Plastisol 200 - metal coating from a polymer 200 microns thick. It is distinguished by volume embossing that imitates the skin or bark of a tree. It was developed specifically for difficult climatic conditions, including industrial zones with a high level of environmental pollution.

Plastisol 100 is half its thickness and is mainly used indoors. It is also made with a coating on both sides and is used for the manufacture of weirs.

- Polydifluorite (PVDF, PVDF2)

Of all kinds metal tile coatings it is the most suitable for decorating facades. It consists of a mixture of polyvinyl fluoride and acrylic in a ratio of 4: 1. It contains high-quality pigments to give shine and color, resistant to prolonged exposure to ultraviolet radiation.

The polymer is quite solid, has hydrophobic properties, which allows it to “repel” dirt, while being quite plastic. It can be matte or glossy.Metal coating can be shiny like metal. For this, it is varnished on top with the addition of a special dye. Resistant to atmospheric and corrosion.

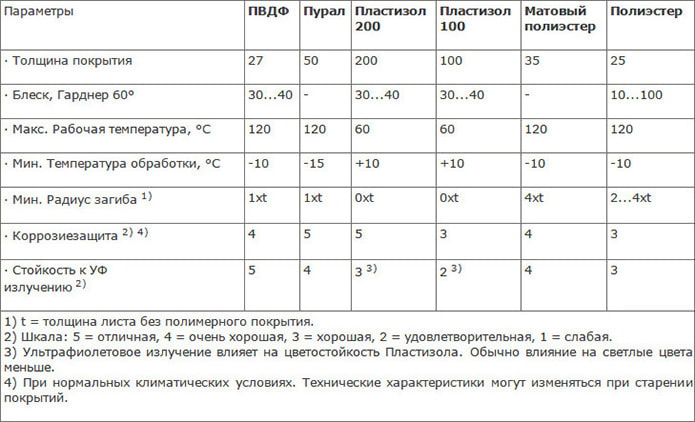

Comparison of the characteristics of metal tile coatings

Installation of ceiling tiles: selection of materials, preparation, procedure

Installation of ceiling tiles: selection of materials, preparation, procedure How to glue the ceiling plinth to the stretch ceiling?

How to glue the ceiling plinth to the stretch ceiling? Ceiling plinth for stretch ceiling: types, recommendations for selection

Ceiling plinth for stretch ceiling: types, recommendations for selection How to choose a screwdriver for home?

How to choose a screwdriver for home? Foam tile for the ceiling: the pros and cons, the stages of gluing

Foam tile for the ceiling: the pros and cons, the stages of gluing Repair in practice: how to repaint furniture yourself

Repair in practice: how to repaint furniture yourself