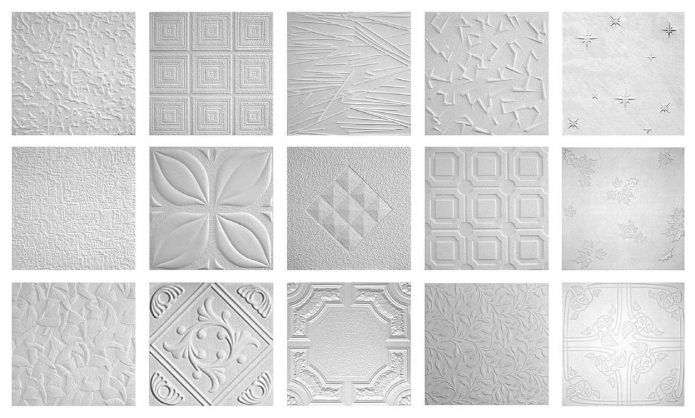

The colors, shapes and volumetric patterns on the tiles allow you to create ceilings of any appearance, they can imitate rough stucco in the country style, and the luxury of stucco molding in the Rococo style, and the caissons of the antique style. Any design request can be met with foam ceiling tiles.

A necessary addition to such a ceiling are decorative skirting boards that close joints and bumps. If desired, they can mount an LED strip for illumination. So that the foam does not shine, after installation it is painted with water-based or acrylic paints.

Kinds

The following types of foam tiles for sale are available on sale:

- Pressed. They have a thickness of up to 7 mm.

- Injection. They have a thickness of up to 14 mm. They are made by sintering the foam at high temperature.

- Extruded. They are made by extruding the polystyrene mass, after which the tiles are either painted or covered with a film with a pattern.

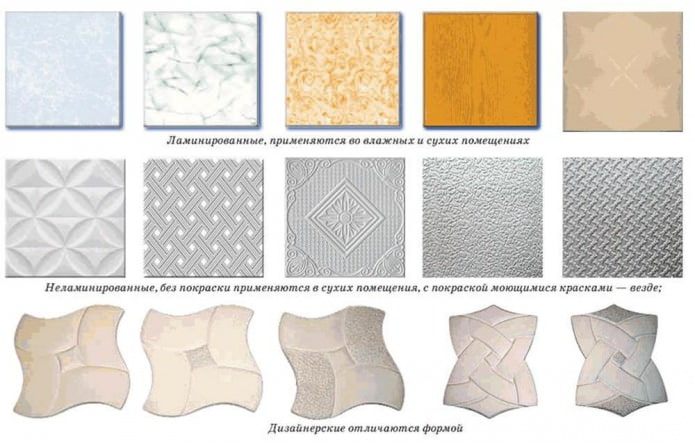

Tiles differ in shape. Most often they are square with a side of 50 cm, but there are also tiles in the form of rectangles, rhombuses, regular hexagons (honeycombs). Also popular is a tile that imitates the shape and coloring of a lining board.

On the front side, the tiles can be smooth or have a relief, simple or covered with a film, laminated. Film, like painting, can imitate the texture of stone, fabric, plaster, wood, stucco, or even woodcarvings. Tiles with lamination are used in rooms reserved for the kitchen. For bathrooms and toilets, panels with waterproof properties are more suitable.

Advantages

The main advantage of such a ceiling coating is that it is very easy to glue the foam tile on the ceiling, and even an unprepared person will cope with it.

In addition, the following advantages can be noted:

- Light weight allows the use of tiles on ceilings of any design.

- The tile has sound and heat insulating qualities, and is not afraid of changes in temperature and humidity.

- The light weight of the tile makes it possible to use a simple glue that does not have ultrahigh strength, and, therefore, a high price.

- This coating for the ceiling will save not only on the material, but also on the work - because it can be done independently.

ATTENTION! Foam tiles on the ceiling can change physical properties (melt) under the influence of high temperature, so installing high-power fixtures in the immediate vicinity is not recommended. It is better to use lighting fixtures, and place them at a distance of at least 20 cm from the surface of the tile. The tile can withstand the temperature of hot water without changing its shape, so it can come into contact with pipes through which it is heated.

disadvantages

Foam ceiling tiles are distinguished by the method of production, quality and price. Cheap tile quickly turns yellow under the influence of ultraviolet radiation, and in some cases is destroyed by moisture. In order to protect it from exposure to light and moisture, it is enough to paint the mounted ceiling with water-based paint.

The main disadvantage is impermeability to moisture vapor. If the ceiling is covered with foam plastic in the room, the walls of which are pasted with vinyl wallpaper, the humidity in the room will increase sharply, which can lead to fungus.

Payment

Before gluing the foam tile to the ceiling, it is necessary to determine how many and which tiles will be needed, why do the calculation, purchase the necessary quantity, and prepare the ceiling surface for installation.

- 1 way: math

For the correct calculation of the number of tiles needed for repair, you need to know the length and width of the room. Multiplication of these numbers will give the ceiling area, but you should not buy tiles taking into account only this figure. Since part of the tiles can be damaged by cutting, moreover, the shape of the ceiling is not ideal, an over-expenditure of material is inevitable. Therefore, be sure to provide a margin of at least 15% of the total area.

For instance, in a 2x3 meter room, the ceiling area is 6 square meters. To cover 1 square meter, you need 4 tiles of a standard size of 50x50 cm. Thus, you will need 24 tiles for pasting the entire ceiling, and another 2-3 tiles as a reserve. In total, you will need to buy 26-27 tiles.

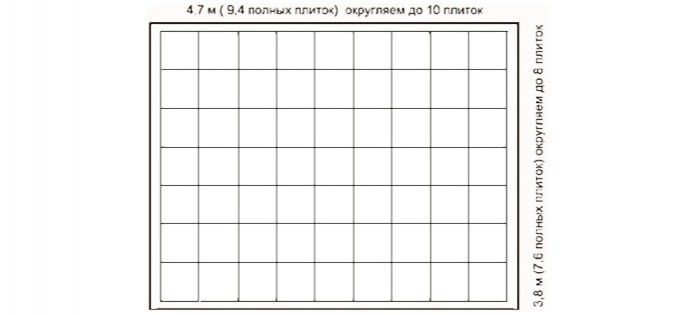

- 2 way: on paper

On a piece of paper you need to draw a plan of the room, while maintaining the scale. Next, you need to draw diagonals and place the tiles from the central part to the edges of the room with maximum accuracy.

If the wall has a gap equal to less than 1/2 of the tile, then 1 pc of tiles will cover 2 of such spaces. If the gap is more than 1/2 of the tile, then it should be noted that a whole tile will be consumed.

Glue

The foam tile is attached to the ceiling with glue, and when choosing it, you need to know some subtleties. So, it is very important how quickly the adhesive sets, how long it dries out completely, and also how thick it is. All this will affect the quality, speed and complexity of the work.

- Choose thick glue, it will not “merge” from the tile and get dirty. Glue “Moment-liquid nails”, for example, has a suitable consistency, in addition, it grasps in 10 minutes - which means that you don’t have to stand for long with your arms extended upwards waiting for the moment when you can let go of the tile. In addition, the consumption of this glue is small - an average of one square meter, or four tiles, takes about 6 ml. Thus, for a medium-sized room, one tube with a capacity of 400 ml is enough, but it is more profitable to take a tube with a volume of 450 ml - this is equipped with a gun with which it is easy to apply glue, in addition, some stock is needed for gluing at the end of the ceiling skirting.

- Another suitable glue is “Titanium”. It is very durable and quickly sets, but there is one subtlety in its application: after applying it to the tile, it must be applied in place, then removed, and kept for one minute in air, then reapplied to the same place and pressed firmly. The main difficulty in this case is to get to the exact same place, especially at the beginning of work.

- It is possible to glue foam tiles onto the ceiling using cheaper adhesives such as Dragon, Eltitans, Power. They are made in China and are not of high quality. The main disadvantage of these adhesives is the long setting time, so you have to stand for a long time with your hands up, which is quite difficult for untrained people.

Tool

Tools for working with foam tiles need a little, and all of them are quite affordable.

You will need:

- masking cord for marking the ceiling before gluing;

- scissors or a special mounting knife for cutting tiles;

- putty knife (as well as putty) for leveling the surface of the ceiling before gluing;

- application roller and primer;

- thread, tape measure and pencil for marking tiles;

- a brush (or gun) for glue, a clean cloth to remove excess material.

Training

Before you start working with tiles for the ceiling of foam, it is necessary to carry out work on the preparation of the surface.

- Tile packaging must be opened a few hours before work. During this time, she will relieve herself of the strain strain that appears as a result of packing in polyethylene, and will accept the temperature and humidity of the room where it will be glued.

- The old coating from the ceiling can not be removed if it is even and durable, in other cases it is necessary to get rid of it. The tile will not be kept on whitewashing, it must be removed without fail.

- If there are significant defects on the ceiling - potholes, crevices, they must be putty. Minor defects do not need to be repaired; they will be covered with tiles.

- Before you start gluing tiles, the ceiling must be primed with a roller to ensure better adhesion of the two surfaces. The primer should dry for at least three hours, and even better - four. After that, you can start marking up.

Markup

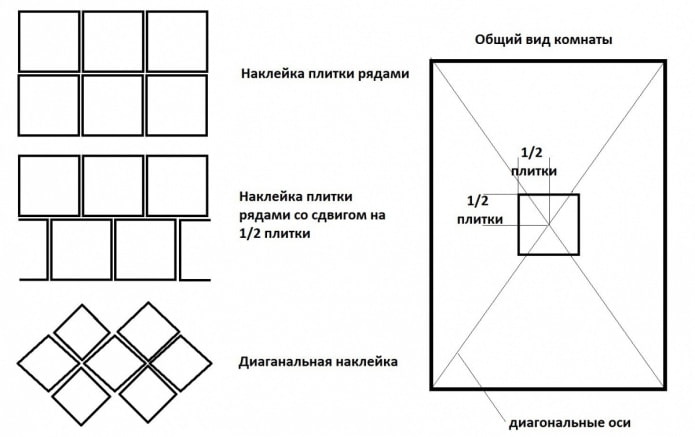

Before gluing the foam tile to the ceiling, it is necessary to outline how it will be located. This is done as follows:

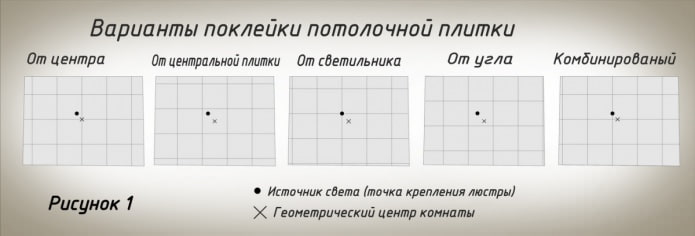

- Define the center of the ceiling. To do this, from the corners of the room they draw through the diagonal ceiling and mark the center of their intersection. You need to do this in any case, you are going to glue the tiles parallel to the walls, or diagonally to them.

- On each wall, find and mark the middle, and stretch a thread between parallel walls - from one mark to another. The thread should go through the center point.

- Perhaps the walls will be of different lengths, and the thread will shift - then you will have to make an amendment.

- Draw lines along the stretched threads with a pencil - they will serve as a guide when gluing the tiles.

Sticking

Tiles can be glued in rows, in rows with a shift, parallel to the walls or in a diagonal direction. Glue on the tile is applied in strips, leaving between them one and a half to two centimeters - otherwise, an excessive amount will be squeezed out when pressed and can get on the front side of the tile, ruining its appearance.

The first foam tile is laid on the ceiling at any angle, from the intersection of the axial at the central point. It must be pressed firmly to the surface and held until the glue sets. If an excess of adhesive mass protrudes along the edges, it will be removed either with a dry cloth, or with a sponge. The second tile glues butt to the first in the second corner from the intersection of the axial. It is also held in place until the glue has set, then released and proceed to continue work.

TIP: Before you start working with foam tiles for the ceiling, check their edges, and if there are burrs, carefully cut them with a sharp knife, otherwise the joints will be visible.

Work continues in a circle, starting from the center and moving to the periphery of the ceiling. When the need arises, the tile is trimmed, for which preliminary marking is done with a pencil. Cutting is best done with a clerical knife.

ATTENTION! Do not forget to cut a hole under the chandelier in the center! After pasting, close joints, if they are visible. The easiest way to do this is with acrylic sealant. At the end of work, let the ceiling dry for a day, and then cover with paint, water-based or acrylic.

Skirting Installation

After completing the painting, you can begin to glue the ceiling plinth. This business has its own tricks that facilitate the work:

- Keeping the baseboard near the wall is more difficult than tile, as it has a large length. Therefore, coated with glue and put in place, the baseboard is fixed with small cloves every half meter, driving them into the wall. After a day, the nails can be removed, and the holes from them sealed with acrylic putty.

- It is very difficult to join the parts of the baseboard, converging in the corners of the room. To make them look beautiful, it is necessary to use a miter box - a special carpentry device for cutting material at an angle. The angle is set at 45 degrees.After gluing the plinth, the cracks in the corners are coated with acrylic putty.

- The final stage of work is the painting of skirting boards with the help of water-based emulsion or acrylic paint.

Installation of ceiling tiles: selection of materials, preparation, procedure

Installation of ceiling tiles: selection of materials, preparation, procedure How to glue the ceiling plinth to the stretch ceiling?

How to glue the ceiling plinth to the stretch ceiling? Ceiling plinth for stretch ceiling: types, recommendations for selection

Ceiling plinth for stretch ceiling: types, recommendations for selection How to choose a screwdriver for home?

How to choose a screwdriver for home? Repair in practice: how to repaint furniture yourself

Repair in practice: how to repaint furniture yourself Stone travertine in decoration and construction

Stone travertine in decoration and construction