Why does the laminate creak?

If the laminate crunches and creaks, look for the reason in one or several factors at once:

- an initially poor-quality laminate with unusable locks and curved geometry was acquired;

- violated climatic conditions of use;

- laying technology is not followed;

- floor leveling not performed;

- no technical gaps left;

- too thick substrate used;

- improper cleaning from dust, debris during installation;

- Temperature, humidity changes occur.

How to remove a creak indiscriminately?

Why does the laminate creak, how to fix this problem without dismantling? If the reason is not in serious violations of the styling technology, perhaps simpler quick ways will help you.

- Paraffin candle. Melt it, pour wax in the places where you hear the sound. If cracks form between the seams, the candle may become a sealant. Processing with a soft spatula will close them and protect them from water and debris.

- Polyurethane foam. It will help with the deflection of floorboards. Put on the nozzle, shake the bottle, fill the foam under the boards in the place where it creaks. Wait for complete drying, remove residues from the surface with a special solution. This method is quite simple, but not too effective - everything will be fine until the foam sags. And it will happen very quickly.

- PVA glue. Used as a substitute for foam. Drill a hole of 0.5 mm (one or more) in the place of an unpleasant sound, remove debris, pour glue into the hole with a syringe. Until completely dry, do not step on this place, it should stop creaking.

- Oil. Life hack is exactly the same as with PVA glue - drill the floor, pour it with a syringe. Lubrication of boards works great on thresholds and other places with constant load.

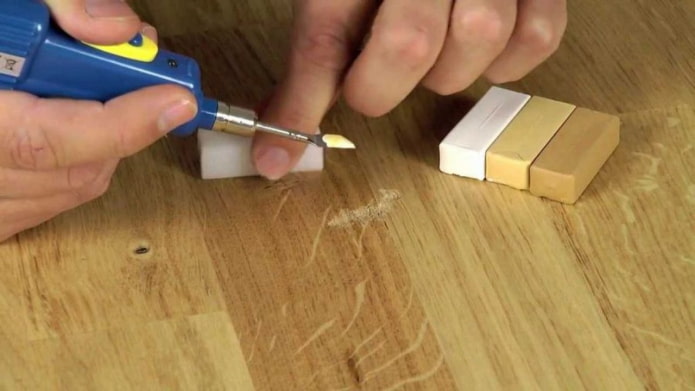

In the photo there is colored wax with which you can close drilled holes

Best ways to eliminate squeaking

If the root of evil lies in materials of poor quality or broken installation technology, most likely you will have to disassemble the floor and put it on a new one. But do not rush with this decision!

Dismantling is not the only way to eliminate the creaking of the laminate. Understanding the cause of unpleasant sounds in the future will help determine the simplest non-cost option for disposal.

Get rid of squeaking due to uneven floors

Poor preparation of the base will lead to one result: the laminate creaks. Any pits or bulges appear when walking, spoil the geometry of the laminate floor.

Unfortunately, to fix the uneven base, you have to disassemble the floor. How much depends on the scale of the problem.

If the laminate creaks in one place, disassemble it before it, cement the cavity or grind the mound, let it dry, put the boards in place.

If the sound is across the floor, it is necessary to dismantle the floor covering, to level it - it is best to use the bulk method, lay the substrate, lay the slats in a new way.

Important: The rickety lamellas cannot be returned to the place, they require replacement with new ones.

Watch the video to find out why it is still not possible to lay the laminate on an uneven base.

What if the laminate creaks due to the temperature gap?

When the laminate does not creak constantly, but with a change in the temperature or humidity of the room - remove the skirting boards and check the condition of the technical clearances.

Laminate boards tend to expand / contract under climatic variations. If during laying the laminate does not leave a distance between the coating and the wall or leave insufficient, when expanding, the strips will quickly abut against the wall. The surface begins to creak, to rattle in separate places.

In the photo, one of the ways to leave gaps when laying a laminate board

When wondering why the laminate creaks, first of all check the climatic gap near the walls and pipes for compliance with the standards:

- the correct clearance for most rooms is 1 cm;

- the distance from the board to the pipe - 1.5 cm;

- the gap between the floor and the walls in wet as well as large rooms is 1.5 cm.

If this is the cause of the creaking of the laminate, the solution will not require dismantling. Masters advise to eliminate this problem by cutting the boards to the required width around the perimeter of the room. At large distances, a grinder will help, a jigsaw - saw off carefully so as not to damage the wall and floor. And around the pipes, cut the laminate with a sharp knife.

We remove the creak of the laminate locks

The tension in the locks is another reason for creaking. If the problem is in it, then an unpleasant sound will appear almost immediately after installation. This is due to the fact that the flooring adapts to the surface of the base, patency, room climate.

The photo shows an example of a laminate floor. After laying, 2-3 months should pass before the lamellas take their final shape and stop creaking.

When the floor settles down, it will take its final form, it will cease to creak by itself. As a rule, this takes up to 3 months. If this does not happen - first of all, check for the presence, size of climatic gaps, following the instructions from the previous paragraph.

How to remove the creak of the laminate due to the remaining debris?

If the laminate creaks while walking, the cause may be sand and other small debris. Dust does not occur by itself, but remains after laying in haste - without thorough cleaning before, during, after installation.

A loud crunch will indicate that sand has got into the locks of the laminate floor. Do not delay the repair of the coating: small specks can lead not only to extraneous sounds, but also damage to the lock joints.

As a rule, it will not be possible to remove the creak of the laminate without disassembling - you will have to remove the lamellas, remove the substrate, clean the base from debris, put the lamellas in a new one. To avoid confusion during reinstallation, number each part before disassembling.

In the photo is a construction vacuum cleaner that will facilitate the cleaning of screed from debris and dust

A crumbling screed can also lead to accumulation of dirt and creak of the laminate. To correct the mistake made, the coating is dismantled to the place where it creaks, poured with cement, leveled, dried well, primed. If you are not sure what you can do, call the wizard for the lighthouse.

Start laying after drying completely. Before starting, thoroughly clean the base, and during - pass through each strip with a vacuum cleaner.

How to fix a creaky laminate if the backing is too soft?

The substrate is the most important layer of the finished floor. It smoothes out small irregularities, protects the laminate floor from water and moisture, dampens noise, and is soundproof and thermally insulated. But more does not mean better. Do not try to solve the drawbacks of the screed, make the flat floor a thickened gasket. A too thick substrate will settle, the laminate on it will begin to bend, its locks will fail, it will certainly begin to creak.

In the photo, a thin cork substrate for laminated panels

The optimal thickness depends on many factors. Including the type of laminate, operating conditions and substrate material. Most often, the manufacturer indicates on the packaging with panels the most suitable option.

Dependence of thickness on material:

- cork - 2-4 mm;

- coniferous - 4 mm;

- foamed - 2-3 mm.

Dependence of thickness on laminate:

- standard 8 mm panels - 2-3 mm;

- thin 6-7 mm - 2 mm;

- thick 9-11 mm - 3-5 mm.

How to eliminate the creak of the laminate due to the substrate? Change! It will be necessary to completely dismantle the coating, replace the old gasket with a new one and re-lay the lamellas.

How to avoid squeaking?

The surest way to remove the creak of the laminate is to do everything from the beginning to avoid it. To do this, you need to know the subtleties of laying this coating and follow the rules.

- Do not use laminate immediately after purchase. Like linoleum, he needs to lie down in the room where he will be bedding. Just leave the boards horizontally for 24 hours in the summer and 48 hours in the winter at room temperature. When they take their final shape, they will be ready for installation.

- Get high quality laminate flooring. Saving on materials can result in many problems: from squeaking and crunching, to deformation, swelling. A more expensive laminate will last much longer without complaints.

- Thoroughly prepare the base. The bulk floor or cement screed should be perfectly aligned, smooth, and durable. If the surface crumbles, you will definitely hear a crunch under your feet. And irregularities and defects will be manifested by sagging, swelling of the boards.

The photo shows an example of high-quality installation: perfectly smooth and clean concrete floor, the right thin substrate

- Choose the right substrate. The most wear-resistant option is cork. It will not bend under the yoke of furniture even after a few years, but is not suitable for use in wet rooms. The most profitable is foamed, but it can deform, thin out. Eco-friendly coniferous bark is often too thick, so it is suitable only for compacted laminate. The optimal thickness of the substrate for use in the apartment is 3 mm.

- Keep clean. Clean the room before laying the substrate and before installing the panels. Keep the vacuum cleaner on hand during installation, remove dust as often as possible. If possible - cut in a separate room.

- Leave temperature gaps. We have already mentioned the ideal distance between the wall and the boards - 1 cm. At a high level of humidity and temperature, increase it by 50 mm. In large rooms also leave gaps between the boards themselves, covering them with decorative strips.

Before starting work, study not only the rules, but also consider the mistakes of others:

Preventing a problem is much easier than getting rid of the squeak after laying. But if you are faced with the problem of extraneous sounds - do not delay the solution. Time can only aggravate the situation, increase the cost of correcting errors.

Top 10 Trends in Interior Design 2020

Top 10 Trends in Interior Design 2020 Rating of cheap TVs with Smart-TV

Rating of cheap TVs with Smart-TV New Year's LED garlands on AliExpress - we disassemble while it is hot so that the house is bright

New Year's LED garlands on AliExpress - we disassemble while it is hot so that the house is bright Wall mural with flowers in the interior: living wall decor in your apartment

Wall mural with flowers in the interior: living wall decor in your apartment Gray sofa in the interior: views, photos, design, combination with wallpaper, curtains, decor

Gray sofa in the interior: views, photos, design, combination with wallpaper, curtains, decor Interior in peach tones: meaning, combination, choice of finishes, furniture, curtains and decor

Interior in peach tones: meaning, combination, choice of finishes, furniture, curtains and decor