Pros and cons

A table made of epoxy can be purchased from masters, made to order or created independently. A description of its features will help to learn more about epoxy furniture, but in the end, aesthetic qualities and exclusivity are the determining factor for most people.

| Advantages | disadvantages |

|---|---|

| The table with the addition of resin is not afraid of mechanical damage, is not scratched from the dishes. | The high price of the source material. |

| Resistant to moisture and easy to clean: a smooth surface can simply be wiped with a wet rag. | When manufacturing, it is necessary to strictly follow the instructions, since even the slightest deviation can lead to product defects. |

| Does not fade in the sun. | Epoxy resin is unstable to low temperatures, the material exfoliates in frost. |

| The material does not shrink after pouring. | When heated, it releases toxic substances (however, in a residential building, the harmfulness of epoxy is minimal, since the air in the apartment does not heat up to dangerous temperatures). |

| It is easily decorated, has an aesthetic appearance and makes it possible to realize any design ideas. | Hot pots and pans are not allowed to be placed on the table with epoxy resin, otherwise the material will melt. |

Types of Epoxy Tables

A variety of models allows you to choose a table for every taste, while each product has its own characteristics. Most often, natural materials are used, the presence of which makes the furniture unique.

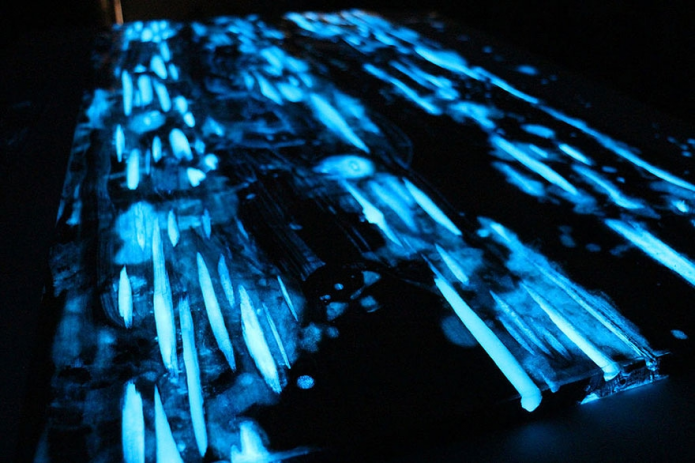

Illuminated epoxy table

Luminous table models equipped with LED strip have a magical effect. Instead of diodes, some masters prefer to use a phosphor. The substance is mixed in a ratio of 1 to 3 (a spoon of phosphor for three tablespoons of epoxy), then the composition is poured into the recesses of the wooden tabletop. Also, resin can cover the entire surface, or combine with a transparent composition of wood slabs. At night, the luminescent glow gives the interior a magical mood.

In the photo there is a table with an epoxy resin backlight. A solution with a phosphor fills the cracks, turning an uneven tabletop into a bright exclusive piece of furniture.

Epoxy table and stone

The basis is a slab or slab of natural stone. Such a massive product looks expensive and impressive, but has a high cost and weight. The stability of the countertop gives the stone base, so the tables are heavy and low. Polishing the surface reveals the beauty of the product: the picturesque swings of rock, its texture and pattern.

The photo shows a low table made of stone. Wave-form epoxy gives the cold rock softness and sophistication.

Epoxy wood coffee table

Wood has many advantages and is an ideal solution for the manufacture of furniture with epoxy resin. This is a malleable material that can be shaped into any shape. Wooden blanks are durable, light weight, it is convenient to work with them. But most importantly, the raw edges of the saw cuts are easily filled with liquid resin, creating picturesque patterns.

If the tabletops made of epoxy resin do not have a wooden base, then the structures can not withstand high loads. In this way only small decorative tables are produced.

In the photo there is a round coffee table made of epoxy resin and wood on a metal support.

Epoxy River Table

The basis of the design are two wood boards, between which the mortar is poured. Most often used oak, ash, elm. The frozen composition repeats the slab irregularities, imitating a river and two banks. Similarity with water is achieved not only due to the form, but also the transparency of the composition, to which blue dye is often added.

Recently, a table-river has become very popular, and not in vain: the glossy surface looks bewitching, and the slices reveal the texture of natural wood. The table can be put in the kitchen, in the living room or study. A luxurious product will decorate any environment and harmoniously fit into the loft, art deco, fusion and eco-style.

In the photo there is a rectangular table made of slab and epoxy mixture with the addition of green dye.

Saw and epoxy table

The frame of the structure can be not only boards, but also wood saw cut. Typically, blanks have cracks, bumps, and even through holes. Thanks to the poured and hardened resin, these shortcomings turn into advantages, giving the product a unique design. For a small table, a wide saw cut with a thickness of 6-8 cm is suitable: the curly edges will give the structure a special shape, and the transparent composition will add elegance to the product.

Small cuts from logs or hemp are also used as decoration: oval and round details of various sizes are laid out on the base and poured with a liquid composition.

In the photo, a tree saw cut from a hollow log, which was presented with a second life, creating a magnificent coffee table.

Decorative epoxy table

With the help of resin, new furniture is created, and the old is restored. All kinds of plant elements are used as decoration for inserts: moss, flowers, leaves, cones.

Epoxy, similar to frozen water, is an ideal material to maintain a marine theme: shells, pebbles, artificial algae are suitable as filling. Masterpieces with hand-painted deserve special attention. To create a three-dimensional image, the resin is poured in stages, and the paint is applied between the layers.

In the photo there is an unusual table, which consists of chipboard and an insert with imitation of the seabed.

An even more interesting version of table design is the use of photographs. To decorate an old countertop, it is necessary to clean it of dirt and polish, then distribute the pictures on the surface. You can take personal photos and create a collage, or print ready-made images. Pictures should be fixed with glue, and the table should have temporary sides (formwork). Pouring resin should begin from the center to the edges, evenly distributing it with a spatula.

In the photo, the decorated tabletop is made of epoxy resin with a painting in the form of fish.

With the addition of dye to the resin

Often, in the manufacture of tables made of epoxy resin, professionals use special tinting agents: the color helps to give the product a special character, make it more memorable and emphasize the author’s idea. The white surface from the hardened resin, similar in color to milk, looks original and allows you to fit the table into any interior. Black dye gives the product rigor and makes it even more respectable. Furniture with multi-colored stains becomes the highlight of the house, and the unique pattern provides it with exclusivity.

In the photo there is a table painted with multi-colored tints using special technology using a hairdryer.

How to make an epoxy table?

We made detailed instructions on how to make a table of wood material and epoxy, and reviewed several popular products for pouring countertops.

What is needed for manufacturing?

To create an epoxy structure you will need:

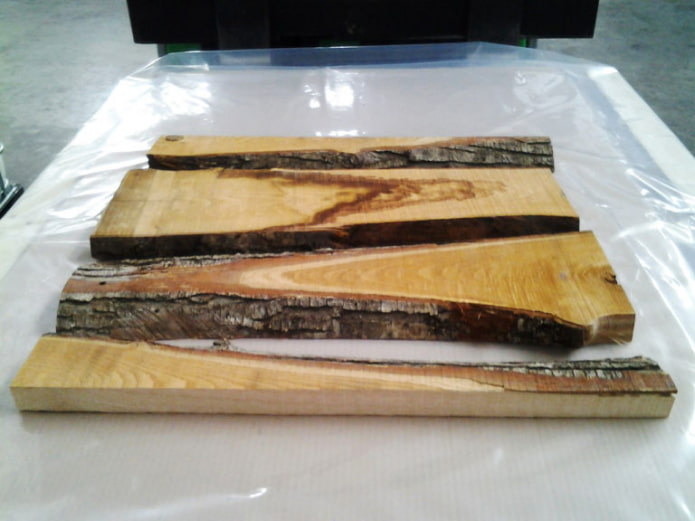

- Slabs or rough boards with jagged edges.

- Epoxy resin (its quantity depends on the size of the structure).

- Jigsaw.

- Grinder.

- Sandpaper of varying degrees of grit.

- Brush.

- Furniture stapler.

- Packing tape.

- Gloves, respirator, goggles.

Which epoxy is better to use?

First of all, it is necessary to choose the right source material. In the manufacture of tables made of wood and epoxy resin, experts choose expensive compounds, because excessive savings can lead to irreparable consequences. A cheap mixture becomes cloudy and yellow over time.

The most popular brands are:

- Crystal Glass. High-quality flowing resin, which is convenient to use when decorating. Thanks to these properties, it easily fills irregularities, penetrates well between small objects (shells, pebbles, herbarium).

- QTP-1130. When hardening, it becomes like glass, it is best suited for pouring with a thin layer. Country of origin Russia.

- PEO-610KE. High-quality resin of average cost remains transparent even under prolonged exposure to sunlight.

- CHS Epoxy 520. Upon purchase, you can immediately purchase a hardener, which is mixed with the main composition according to the instructions. The composition allows you to fill the layers up to 5 cm without the formation of cracks.

- "Art Eco". Transparent composition of domestic production. The same company produces colors that can be used for a more interesting result.

What is the thickness of the epoxy to use for tables? A liquid agent that flows freely from a stick perfectly permeates the tree, filling all the hollows. But you need to be careful when sealing the mold so that the mixture does not leak out of the microscopic holes. The semi-liquid consistency is suitable for filling tables and joining wooden parts, but a thick resin is only appropriate for the restoration of solid wood furniture and the creation of jewelry.

Step-by-step instruction

When creating a table made of epoxy resin, it is important to adhere to the technology. Procedure:

- First of all, you need to choose slabs: it can be a slab with a convex side, several saw cuts with bumps or rough boards. The tree must be dry.

- At the next stage, it is necessary to process the workpieces: we eliminate the irregularities that formed during the cut with a jigsaw. We cover the boards with a thin layer of epoxy using a paint brush. The composition impregnates the tree, sealing the pores: subsequently, it will help protect the filler countertop from the appearance of bubbles.

- After processing the wood, we make a mold for a homemade table. Sliding formwork can be made of chipboard, plywood or wooden battens. The dimensions of the form should correspond to the future table. We carefully fix the film. It is best to choose a special material that does not crease and easily peels off.

-

We prepare the epoxy resin in accordance with the instructions. This requires two containers. Mix the solution slowly, add color if desired. After heating it in a water bath to 30-40 degrees, pour the hardener. Bring the mixture to homogeneity, then gently fill the workpiece with a thin stream. You need to pour at one point. First, fill the space between the boards, and after hardening, completely fill the area of the table. If necessary, smooth the surface with a spatula. Bubbles blow a hairdryer.

- The resin hardens best in a warm room. Usually the process takes about two days. After that we eliminate excess resin and roughness by grinding. For protection, we cover the tabletop with polyurethane varnish.

- We fix the legs for the table made of epoxy resin. Suitable wooden supports of oak, larch, beech or metal from aluminum or steel.

- Do-it-yourself square table made of epoxy resin and wood:

Do-it-yourself video instruction: master class for beginners

At home, creating unique furniture is quite difficult, but interesting - you need woodworking skills and the availability of tools. How to make an epoxy table is detailed in this video tutorial:

Ideas for tables in the interior

Epoxy furniture is not only beautiful, but also durable, and it is not afraid of moisture.The countertop can serve as a kitchen worktop or a place for computer equipment. Also, the resin will help to perpetuate a valuable collection, as in the example with a bar counter, the surface of which is decorated with multi-colored beer lids.

In the photo there is a narrow high table with a transparent insert that will decorate any hallway.

Tables using epoxy resin look light and airy: if there is not enough space in the kitchen, a transparent surface will help visually relieve the space.

In the photo there is a comfortable and outwardly attractive dining table on a metal support.

Some masters do not stop there and come up with new types of tables. Of particular value are the "space" countertops. They are created using several types of colors, mixing dyes right during pouring and creating intricate patterns with a hairdryer.

Photo gallery

Amazing designer products will decorate any interior and bring an element of luxury to the decor. With proper persistence and diligence, you can independently make a table or console made of epoxy resin: the main thing is to follow safety precautions, strictly follow the instructions and take into account the recommendations of specialists.

Top 10 Trends in Interior Design 2020

Top 10 Trends in Interior Design 2020 Rating of cheap TVs with Smart-TV

Rating of cheap TVs with Smart-TV New Year's LED garlands on AliExpress - we disassemble while it's hot, so that the house is bright

New Year's LED garlands on AliExpress - we disassemble while it's hot, so that the house is bright Wall mural with flowers in the interior: living wall decor in your apartment

Wall mural with flowers in the interior: living wall decor in your apartment Gray sofa in the interior: views, photos, design, combination with wallpaper, curtains, decor

Gray sofa in the interior: views, photos, design, combination with wallpaper, curtains, decor Interior in peach tones: meaning, combination, choice of finishes, furniture, curtains and decor

Interior in peach tones: meaning, combination, choice of finishes, furniture, curtains and decor